As the world transitions to greener energy sources, Compressed Natural Gas (CNG) has emerged as a reliable, clean-burning alternative fuel. It’s an efficient choice that reduces emissions and supports sustainable energy efforts, particularly in the transportation sector. With CNG being increasingly adopted as a fueling option for transportation, the demand for specialized knowledge in maintaining and operating CNG fueling systems has risen significantly. Essential to this growing infrastructure are the mechanics and technicians responsible for the upkeep and service of the high-pressure systems and compressors that enable CNG fueling. Recognizing the need for well-trained, knowledgeable professionals, Ariel Corporation—a leading manufacturer of compressor systems—offers a Specialty Original Equipment Manufacturer (OEM) course. This program is meticulously crafted for mechanics and technicians overseeing the service and operations of Ariel CNG compressor equipment, providing them with the specialized skills needed to excel in the field of CNG transportation fueling.

Why Specialized Training for CNG Compressors Matters

CNG compressors are vital to the CNG fueling process, enabling the safe and efficient transfer of natural gas into vehicles. These high-pressure systems require an advanced understanding of engineering principles and precise handling to maintain both safety and performance. Compressing natural gas to high pressures requires specialized equipment that operates under significant strain. Without proper maintenance, these systems can suffer from reduced efficiency, performance issues, and increased risk of operational hazards.

Ariel’s compressors are widely recognized for their durability and performance. However, even the most reliable equipment needs regular, skilled maintenance to perform at its best. Ariel’s Specialty OEM Course focuses on equipping professionals with the advanced skills required to manage these high-pressure systems safely and effectively, ensuring that they have the expertise to keep CNG compressors running smoothly in even the most demanding conditions.

A Detailed Overview of Ariel’s OEM Training Course

Ariel’s training program is a comprehensive educational experience that covers every aspect of CNG compressor service, from safety protocols and maintenance best practices to system diagnostics and troubleshooting. The course structure emphasizes hands-on learning, ensuring that participants not only learn theoretical concepts but also get practical experience working with the actual equipment they’ll encounter in the field.

1. Hands-On Learning Experience

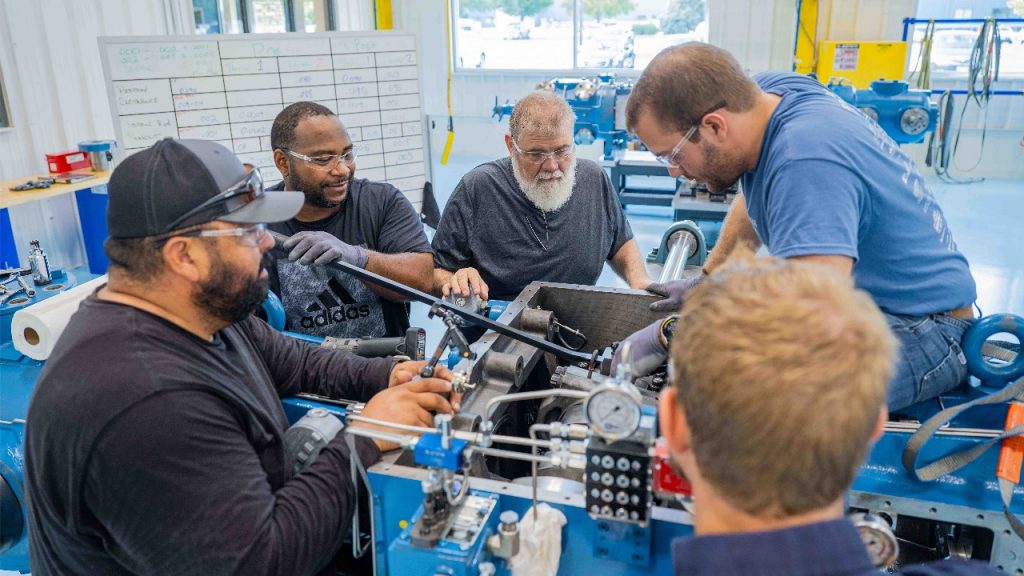

One of the standout features of Ariel’s OEM course is its emphasis on practical learning. Participants engage in hands-on training that immerses them in the real-world scenarios they’re likely to encounter on the job. By working directly with Ariel’s compressor systems, technicians gain a deeper understanding of each component, from core mechanical parts to intricate electronic control systems.

This hands-on approach is essential for building the confidence needed to handle complex CNG compressors. Mechanics and technicians are trained to perform routine maintenance, diagnose issues, and carry out necessary repairs. This experience ensures that they’re fully equipped to manage the technical challenges they may face in the field.

2. In-Depth Knowledge of Ariel Compressor Systems

Ariel’s OEM course provides an exhaustive exploration of their CNG compressor models. Participants receive detailed instruction on every aspect of the compressor system, from the functionality of individual parts to the intricacies of high-pressure dynamics. By the end of the course, mechanics and technicians are expected to understand the complete compressor system, including the inner workings of critical components and their role in overall system functionality.

The course doesn’t just focus on teaching participants to “fix” issues; it trains them to understand the why and how of each compressor component’s function. This depth of knowledge enables technicians to make informed decisions and take proactive steps in maintaining and operating CNG compressors. Equipped with this expertise, they’re better prepared to maximize equipment efficiency and reliability, reducing the likelihood of costly downtime.

3. Safety Protocols and Best Practices

Safety is paramount when working with high-pressure systems, especially those designed for CNG fueling. Ariel’s OEM course dedicates significant time to instilling a strong safety mindset in participants. The course covers essential safety protocols tailored specifically to the high-pressure demands of CNG compressors, emphasizing Ariel’s commitment to strict safety standards.

Participants learn to recognize and mitigate potential hazards, ensuring that they follow best practices for safe operation and maintenance. Ariel’s program emphasizes hazard identification, emergency procedures, and preventive measures, enabling technicians to operate equipment safely, even in high-stakes environments. By training participants to prioritize safety at every step, Ariel helps reduce the risk of accidents and ensures that its compressors are operated according to the highest industry standards.

4. Certification for Specialized Expertise

Upon completing the course, participants earn a certification that sets them apart as specialists in Ariel CNG compressor equipment. This certification is a valuable asset in the CNG transportation industry, as it signifies that the individual has the advanced skills and knowledge needed to maintain and operate high-pressure CNG fueling systems effectively.

The certification also opens doors to greater career opportunities. As demand for CNG continues to grow, companies are increasingly seeking qualified technicians who can confidently service CNG fueling equipment. Ariel’s certification is a mark of excellence that employers recognize and value, making certified technicians highly sought after in the industry.

5. Ongoing Support and Access to Resources

Ariel’s commitment to quality and service doesn’t end when the course concludes. Graduates of the OEM course gain access to a network of resources, including troubleshooting guides, technical support, and consultation with Ariel experts. This ongoing support is invaluable, as it enables technicians to keep their skills sharp and stay up-to-date with the latest advancements in CNG compressor technology.

Additionally, Ariel provides access to a knowledge base that technicians can refer to as they encounter unique challenges in the field. This continuous access to resources ensures that graduates of the course are always equipped with the latest information and can continue to excel in their roles long after they’ve completed their training.

Who Should Consider Enrolling in Ariel’s OEM Course?

Ariel’s OEM course is designed for a wide range of professionals in the CNG fueling sector. It’s ideal for mechanics, technicians, and operations managers responsible for the service and maintenance of CNG fueling systems. Whether they’re new to the field or experienced professionals looking to specialize in Ariel equipment, participants will find that this course provides the knowledge and skills they need to succeed.

The course is particularly valuable for those working in high-pressure environments or with systems that require specialized maintenance. The skills gained through this program can enhance a technician’s career prospects while equipping them to make a meaningful contribution to the CNG industry’s growth.

Benefits of Specializing in CNG Compressor Service and Operations

As investments in CNG infrastructure continue to rise, there’s a growing demand for skilled technicians who can maintain and operate CNG compressors. Specializing in CNG compressor service and operations provides numerous benefits, both for individual technicians and the industry as a whole.

For technicians, this specialization opens doors to rewarding career opportunities. With a certification from Ariel’s OEM course, technicians can command higher salaries, gain access to more advanced positions, and enjoy greater job security. Their specialized skills make them valuable assets in a rapidly expanding industry, where qualified professionals are in high demand.

For the industry, having well-trained professionals available to maintain CNG infrastructure is essential. CNG fueling systems are a critical part of the push for cleaner energy solutions, and ensuring these systems operate smoothly and safely is paramount. Technicians trained through Ariel’s OEM course bring a level of expertise that enables companies to maximize the efficiency and lifespan of their equipment, reducing costs associated with downtime and repairs.

Conclusion

Ariel’s Specialty OEM course is more than just a training program; it’s an investment in the future of sustainable energy. By equipping mechanics and technicians with specialized knowledge in CNG compressor service and high-pressure system management, Ariel plays a vital role in advancing the adoption of CNG as a cleaner fuel alternative.

For mechanics and technicians, this certification offers an opportunity to expand their careers while directly contributing to the industry’s move toward greener energy. By mastering the skills needed to maintain and operate CNG fueling systems, these professionals are supporting a future where clean, efficient, and sustainable energy is accessible to all. Ariel’s dedication to excellence, safety, and innovation ensures that graduates of the OEM course are well-prepared to meet the challenges of the evolving energy landscape.